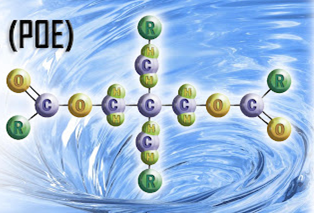

POE oils are synthetic polyol ester-based lubricants designed for use as compressor fluids in refrigeration systems. These oils exhibit excellent water tolerance and low-temperature properties, resulting in favorable flow points for refrigerant-oil mixtures. Additionally, they are favored for providing better lubrication and stability, as well as greater compatibility with HFC refrigerants compared to similar synthetic and mineral oils.

Features and Benefits:

- POE oils are excellent lubricants that are less hygroscopic than PAG types and are chemically more stable in the presence of water than PAGs. They are designed for use in all refrigeration and air conditioning applications.

- Low freezing point

- Very good flow properties at low temperatures

- High thermal and chemical stability

Performance

- Excellent chemical stability, even at low temperatures, and fully compatible with environmentally friendly HFC refrigerants such as R134A.

- Outstanding oxidation stability at high temperatures, controlling evaporation and the production of oxides, maintaining evaporator cleanliness, and improving compressor efficiency.

- Excellent fluidity at low temperatures, reducing the risk of oil storage issues and line blockages, and enhancing evaporator performance.

- Retention of lubricating properties in high or low-temperature environments, controlling wear and protecting key compressor components.

- Good hydrolytic stability, preventing corrosion of compression parts.

- Compatible with mineral oils, alkyl benzene (AB), polyalphaolefin (PAO), and polyvinyl ether (PVE).

Applications

POE oils are compatible with refrigerants R-134a, R-410A, and R-12. They are used as lubricants in systems utilizing HFC-134a, especially when CFC-12 is being replaced, as these systems traditionally used oils that do not mix well with HFC-134a. These oils are employed in chlorine-free hydrofluorocarbon (HFC) refrigeration systems, as they provide better lubrication and stability and have greater compatibility with HFC refrigerants compared to similar synthetic and mineral oils.

Key Differences Between POE Oil and Mineral Oil

POE oil (Polyolester Oil) is a synthetic lubricant created through the esterification of polyols and fatty acids, characterized by its polar nature. In contrast, mineral oils are natural lubricants derived from petroleum.

Here are the key differences between them:

Chemical Properties: POE oil is a synthetic lubricant known for its high polarity and chemical stability, allowing it to maintain effective lubrication across a wide temperature range. On the other hand, mineral oil is a natural lubricant that tends to be chemically less stable.

Functional Performance: POE oil exhibits excellent heat resistance and oxidation stability, retaining its lubricating properties even under high temperature and load conditions. In contrast, mineral oil has relatively inferior lubricating performance and is prone to decomposition and oxidation when exposed to high temperatures and loads.

Environmental Impact: POE oil is biodegradable and has a lower environmental impact, whereas mineral oil is not easily degradable and poses a greater risk to the environment.

Cost: POE oil is generally more expensive, while mineral oil is more affordable.

In practical applications, POE oil is commonly used in lubrication systems that require high temperature, high load, high speed, or high cleanliness, such as compressors and refrigeration equipment. Mineral oil, however, is typically used in general lubrication systems, including machine tools and transmission systems.

POE oil differs from mineral oil in four key aspects:

Moisture Absorption

Mineral oil is not hygroscopic and does not absorb water molecules, so there is usually no concern about moisture absorption with mineral oil. Whenever you install or open systems that use POE oil, a deep vacuum must be created. The system should then remain completely sealed and only opened for servicing. POE oil is so hygroscopic that it can absorb moisture through plastic.

Hydrolysis

POE oil not only absorbs moisture but also reacts with water, breaking down into its base components, namely acids and alcohols. This process is irreversible, and these acids can damage metal lines and components. As a result, you may encounter copper plating in the compressor and potential burnout. Therefore, if you suspect oil contamination, an acid test should be performed.

Additives Materials

POE oil contains certain additives, including corrosion inhibitors. While POE oil appears to be a complete liquid, these additives are actually solid materials. Whenever any type of additive is present, whether they are mixed with the oil or added to the system, care must be taken to prevent the refrigerant from cooling too much. Cold spots in the system can cause solids to start accumulating, which can lead to clogging of filters and driers.

Polarity

The molecular structure of POE, PAG, and PVE oils makes them hygroscopic, but water is not the only thing these molecules attract.

POE oil is polar, meaning its molecules cling to things like scale buildup inside the lines. As this POE oil moves through the lines, it strips cupric oxide from the insides of the piping. This black scale can clog filters, valves, and lines.

افزودن دیدگاه