Improvement and enhancement of product quality

- home

- >

- Improvement and enhancement of product quality

Engineering and installation services

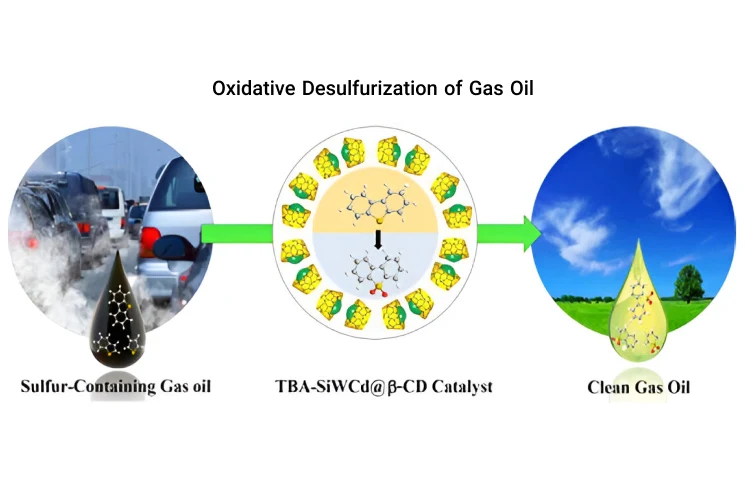

Desulfurization

Sulfur compounds rank among the most prevalent impurities in crude oil. The inclusion of sulfur in liquid fuels results in the release of SO2 and sulfate particles, which can endanger public health and property while also shortening the lifespan of engines due to corrosion. Eliminating sulfur from oil is vital from an environmental standpoint, as burning sulfur compounds generates sulfur oxides, contributing to acid rain. As regulations concerning sulfur levels in fuels become more stringent, the industry utilizes a range of desulfurization processes to comply with these requirements.

Improvement of the final product quality

Reduction of Hydrocarbons

Reducing sulfur hydrocarbons in motor oil and its derivatives contributes to the overall quality improvement of these products. This leads to enhanced lubrication properties, reduced wear and damage to engine components, decreased pollutant emissions, and improved fuel efficiency. Below are some benefits of reducing sulfur in motor oil:

· Reduction of Wear and Damage to Components

Lower sulfur levels help reduce wear and damage to engine parts, which in turn increases the engine's lifespan.

· Improvement of Lubrication Properties

Motor oil with lower sulfur content exhibits better lubrication properties, aiding optimal engine performance and reducing friction.

Decrease in Pollutant Emissions

Reducing sulfur contributes to lower emissions of pollutants and harmful substances during combustion, leading to improved air quality and reduced environmental impact.

Increased Fuel Efficiency

With improved oil quality, fuel efficiency is enhanced, resulting in more optimal fuel consumption.

Improvement of the final product quality

Specialized Tests and Experiments

By conducting these specialized tests, manufacturers can develop high-quality engine oils that enhance lubrication, reduce wear, and improve overall engine performance.

Oil Formulation Testing

Laboratory tests evaluate the effects of different oil formulations on component friction.

Fired engine tests assess the performance of oils under real operating conditions.

Viscosity Analysis

Viscosity is measured at specific temperatures (such as 40°C and 100°C) to determine the oil's resistance to flow.

High Viscosity Index (VI) oils are preferred for engines operating at elevated temperatures to prevent thinning.

Contamination Control

Regular oil analysis helps identify contaminants such as fuel dilution, water, and wear particles.

Techniques like gas chromatography are used to measure fuel dilution levels, while infrared analysis detects water content.

Oxidation and Thermal Stability Testing

Differential infrared analysis measures the level of oxidation in oil, which can lead to harmful deposits and increased viscosity.

Tests assess the presence of nitration products formed during combustion, which can accelerate oil degradation.

Wear Particle Analysis

Elemental analysis quantifies wear metals to identify potential issues in engine components.

Monitoring wear particles helps in trend analysis and early detection of mechanical problems.

Friction and Wear Testing

Friction tests simulate engine conditions to evaluate the lubricating properties of oils.

These tests help in understanding how different oils perform under stress and their ability to reduce wear.

Additive Effectiveness Evaluation

The performance of additives in controlling oxidation, wear, and corrosion is assessed through various tests.

This ensures that the oil maintains its protective qualities over time.

Improvement of the final product quality

Implementation of Advanced Quality Control Systems

The implementation of advanced quality control systems in the engine oil industry aims to enhance performance and extend the lifespan of engines by utilizing modern analysis and monitoring techniques for oil quality. These systems conduct regular and precise tests, such as chemical and physical analyses, to identify contaminants, viscosity changes, and wear particles. Additionally, by monitoring the performance of additives and conducting periodic evaluations, these systems can predict and prevent potential issues in the engine. As a result, manufacturers can provide higher-quality oils that are more compatible with the needs of modern engines, ultimately improving efficiency and reducing maintenance costs.