Oil additive

- home

- >

- Oil additive

Lubricant Additives

Lubricant Additives

Professionals in lubrication typically develop a strong understanding of the viscosity of the base oils used in their equipment lubricants, as viscosity is a key characteristic of these oils. Standards for incoming oils are established, and the condition of the lubricant is assessed primarily based on viscosity. However, it's important to recognize that lubricants encompass more than just viscosity. Understanding the role and functions of additives within the lubricant is essential. Lubricant additives are either organic or inorganic substances that are either dissolved or suspended as solids in the oil.

Hydrocarbon Derivatives

Three basic purposes of additives

Grasping the physical properties and chemistry of lubricant additives is essential.

Lubricants play a vital role in the smooth operation and longevity of machinery by minimizing friction, wear, and heat. Their effectiveness relies not only on base oils but also significantly on lubricant additives, which improve performance and durability through their distinct physical properties and chemistry.

They improve the inherent properties of the base oil through the use of antioxidants, corrosion inhibitors, anti-foam agents, and emulsifying agents.

They mitigate unfavorable characteristics of the base oil by employing pour-point depressants and viscosity index (VI) improvers.

They introduce new properties to base oils with the help of extreme pressure (EP) additives, detergents, metal deactivators, and tackiness agents.

Hydrocarbon Derivatives

Conventional Lubricant Additives

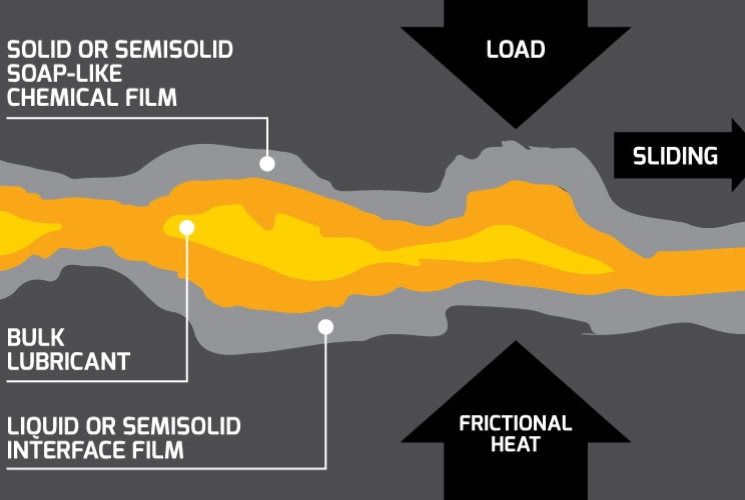

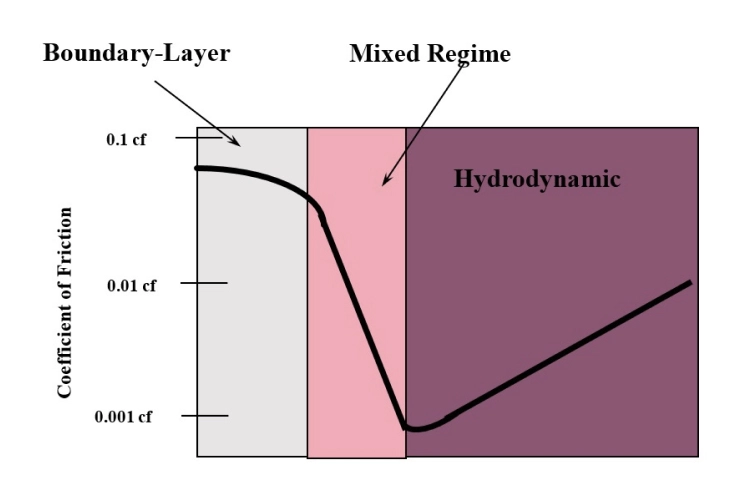

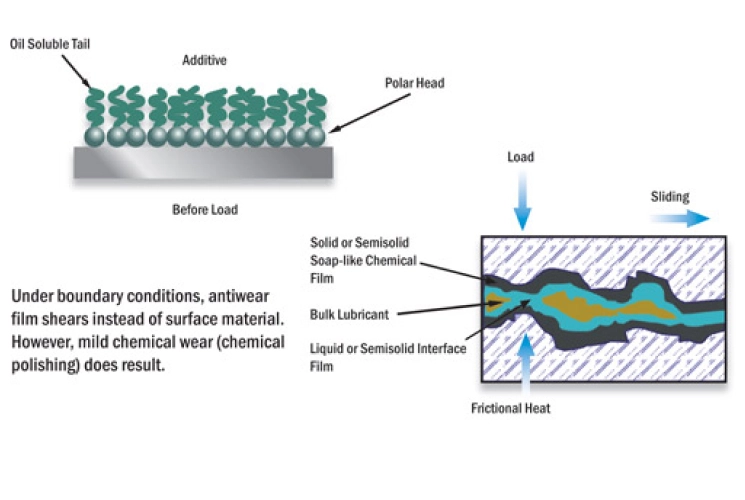

These additives are commonly employed to safeguard machine components from wear and metal loss under boundary lubrication conditions. As polar additives, they bond to frictional metal surfaces. When metal-to-metal contact occurs in mixed and boundary lubrication scenarios, they chemically react with the metal surfaces. Activated by the heat generated during contact, they create a film that reduces wear. Additionally, they protect the base oil from oxidation and shield the metal from corrosive acids. These additives are consumed as they perform their protective function, leading to increased adhesive wear damage once depleted. They are primarily phosphorus compounds, with zinc dialkyldithiophosphates being the most prevalent.

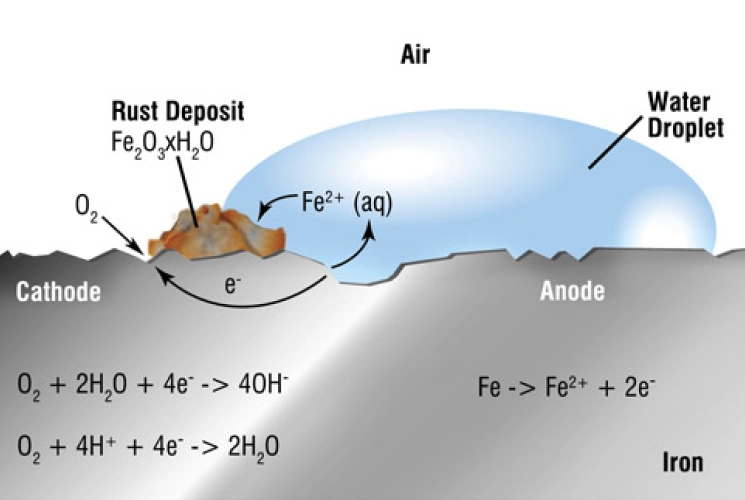

Rust and corrosion inhibitors are vital for protecting metal surfaces in industrial environments, where moisture, salt, and other corrosive elements can cause serious damage.

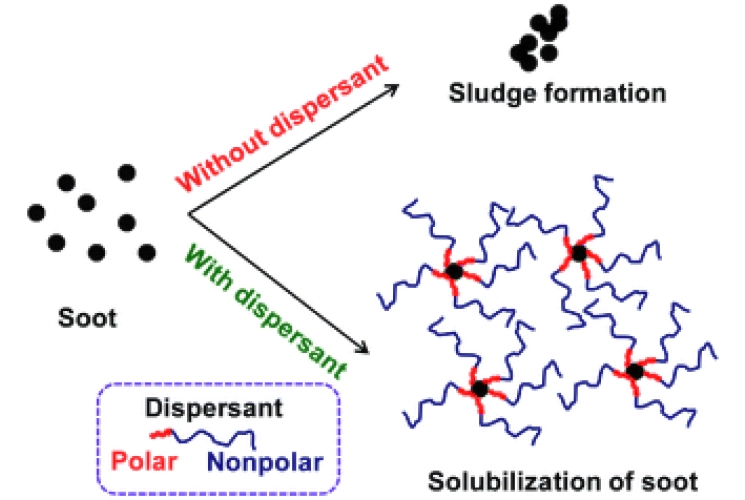

Detergents and dispersants play crucial roles in maintaining engine cleanliness. Detergents prevent deposits on hot metal parts and neutralize acids formed in the oil, while dispersants work alongside them to keep diesel engine soot particles, typically under 1 micron, finely dispersed in the oil, reducing clumping and potential damage.

Viscosity index improvers (VII), also known as viscosity modifiers or viscosity enhancers, are polymer additives that adjust the viscosity of fluids and lubricants across their entire operational temperature range.

The pour point is the lowest temperature at which a lubricant remains fluid. At low temperatures, wax crystals in mineral oils solidify (crystallize), hindering the oil's ability to flow smoothly. This is where pour point depressants come into play. They decrease the size of the wax crystals in the oil, enhancing its flowability even at sub-zero temperatures.

Anti-foaming agents, including silicone polymers and organic copolymers, lower surface tension to prevent foam formation in lubricants. By reducing the contact between oil and air, they can also help decrease oxidation risk. Only small amounts are used in oil formulations, as excessive quantities can lead to increased bubbling.

Oxidation is the process where oxygen in the air attacks the weakest components of base oil, occurring continuously but accelerating at higher temperatures and in the presence of water, wear metals, and other contaminants. This leads to the formation of acids, which cause corrosion, and sludge, which increases viscosity and creates surface deposits. Oxidation inhibitors, or anti-oxidants, are sacrificial additives that help prolong the oil's lifespan by delaying oxidation.

| Prolong the lubricant's lifespan by preventing oxidation, and helps reduce base oil thickening, sludging, and the formation of deposits. | Antioxidants |

| Selected to interact with harmful contaminants like acids or sulfur to make them less detrimental. | Scavengers |

Table 1. Additives Functioning Within the Grease Matrix

| Reduce wear, especially in high-speed, low-load operating conditions. | Antiwear Agents |

| Prevent metal corrosion in contact with the lubricant, safeguarding equipment and prolonging the lubricant's lifespan. | Corrosion inhibitors |

| Prevent seizure in high-load and high-temperature conditions. | Extreme Pressure (EP) Agents |

| Minimize friction between moving components through surface adsorption. | Friction Modifiers |

| Prevent metals in contact with the lubricant from catalyzing its oxidation. | Metal Deactivators |

| Support elastomer seals and gaskets in fulfilling their role. | Seal Swell Agents |

Table 2. Additives Acting at a Surface

Hydrocarbon Derivatives

Antifreeze and Coolants

The main role of the cooling system is to remove excess heat generated by the engine during operation. The coolant absorbs this heat and carries it to the radiator, which acts as a heat exchanger, releasing the heat into the outside air.

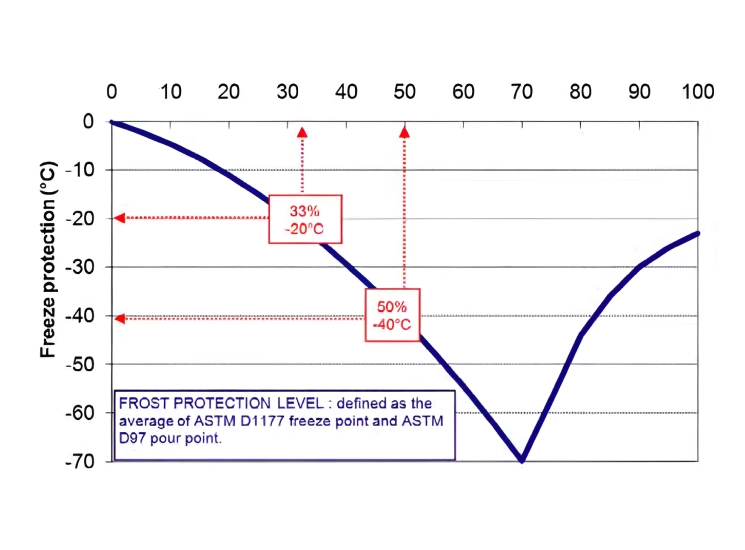

Antifreeze and coolants often receive well-deserved attention. Antifreeze is a concentrated product made up of 90-95% Mono Ethylene Glycol (MEG) and 5-10% additives. In contrast, coolant is a 50/50 mixture of antifreeze and demineralized water. The level of frost protection depends on the antifreeze concentration in the water.

A typical modern antifreeze/water mixture balances frost protection and heat transfer efficiency.

While a 70% antifreeze and 30% water mixture offers optimal frost protection, the low water content significantly reduces heat transfer capabilities, risking engine overheating. As a result, most standard "ready-to-use" coolants are formulated with a 50/50 ratio of antifreeze to water, which generally provides adequate frost protection for most regions while maintaining excellent heat transfer properties.

Hydrocarbon Derivatives

API SL Motor Oil Additive Package

Description

SL motor oil is a category of benzene engine oil designed to safeguard the engine from wear, corrosion, oxidation, and various other forms of damage. Furthermore, it offers improved lubrication for the moving parts of the engine and aids in reducing friction among these components.

Applications

The (API SL) quality level of engine oil is suitable for gasoline engines produced between 2002 and 2005. This oil features improved manufacturing technology compared to the SJ model and complies with environmental.

standards.Basic Info

| Motor oils | Application |

| red viscous liquid | Appearance |

| 6.5-8.0 | Viscosity Index |

| 0.991-1.031 g/cm³ | Density (20ºC) |

Storage

storing items in a cool place and avoiding direct sunlight when stored at room temperature.

Package

In a metal drum/ IBC

Hydrocarbon Derivatives

API Sn Gasoline Engine Oil Additive Package

Description

The API SN quality standard was introduced in 2010 and is considered a suitable option for engines manufactured with modern technologies from that year onward. The characteristics of oils meeting the SN standard include deposit control, oxidation resistance, excellent lubrication, good performance at low temperatures, and reduced fuel consumption.

Applications

This category of engine oil is categorized based on viscosity grades as per the SAE J 300 standard. However, the viscosity grades specified in this standard are restricted to multi-grade engine oils, including SAE 0Wx, SAE 5Wx, SAE 10Wx, and SAE 15Wx.

standards.Basic Info

| Packing & Shipping | Application |

|---|---|

| Brown viscous liquid | Appearance |

| 131 mm²/s | Kinematic Viscosity(100°C) |

| 0.953-0.993 g/cm³ | Density (20ºC) |

Storage

storing items in a cool place and avoiding direct sunlight when stored at room temperature.

Package

In a metal drum/ IBC

Hydrocarbon Derivatives

API CI₄ Diesel Engine Oil Additive Package

Description

The API CI-4 group was introduced in 2002 for high-speed four-stroke diesel engines that comply with the 2004 emissions regulations. Oils classified under API CI-4 are specifically designed to enhance engine longevity in systems that utilize exhaust gas recirculation (EGR) and other emissions control technologies. These oils are suitable for diesel fuels with a sulfur content of up to 0.5% by weight. They provide excellent protection against corrosive wear, maintain stability at both low and high temperatures, effectively manage soot, control piston deposits, reduce valve train wear, prevent oxidative thickening, minimize foaming, and prevent viscosity loss due to shear. Oils that meet the API CI-4 standards offer improved performance and can replace oils classified as API CD, CE, CF-4, CG-4, and CH-4.

Applications

Oils that meet this specification are designed for high-speed four-stroke diesel engines typically used in heavy-duty applications. These oils effectively enhance engine durability. The use of API CI-4 oils helps protect against component wear and provides stability at both low and high temperatures. They also perform well in managing soot, controlling piston deposits, reducing valve train wear, preventing oxidative thickening, minimizing foaming, and preventing viscosity loss due to shear. Additionally, API CI-4 oils are compatible with API CH-4, API CG-4, and API CF-4 oils, making them suitable for use in applications where these oils are recommended.

standards.Basic Info

| Suitable for new and older powered vehicles, diesel-powered equipment | Application |

|---|---|

| Bright & Clear | Appearance |

| 174 | Viscosity Index |

| 0.852 g/cm³ | Density (20ºC) |

Storage

storing items in a cool place and avoiding direct sunlight when stored at room temperature.

Package

In a metal drum/ IBC

Hydrocarbon Derivatives

API GL-4 Gear Oil additive package

Description

API GL-4 Formulated with paraffinic base stocks, it includes a precisely balanced additive package of sulfur and phosphorus for extreme pressure, ensuring gear protection, effective rust and corrosion resistance, and extended lubricant life. GL-4 delivers value through: Good gear life, Rust and corrosion protection, Market general performanc, Good lubricant life, Seal Protection. API GL-4 oils are formulated for manual transmissions that experience light to heavy loads and sliding forces.

Applications

Gear Oil GL-4 is formulated for use in automotive transmissions, steering systems, and hypoid drive axles that necessitate a fluid meeting API GL-4 performance standards. The friction properties of the Gear Oil GL-4 range make it appropriate for many synchronized manual transmissions.

standards.Basic Info

| Gear lubricants are advised for use in modern vehicles, bearings in steering axles, | Application |

|---|---|

| Bright & Clear | Appearance |

| 100-105 | Viscosity Index |

| 0.909 g/cm³ | Density (29.5ºC) |

Storage

storing items in a cool place and avoiding direct sunlight when stored at room temperature.

Package

In a metal drum/ IBC

Hydrocarbon Derivatives

API GL-5 Gear Oil Additive Package

Description

API GL-5 specification gear oils are designed for extreme conditions and contain up to 6.5% effective anti-scuff additives. These oils are primarily intended for hypoid gears with significant axis displacement. They are recommended as universal oils for various mechanical transmission units, excluding gearboxes.

Applications

Oils in this category, which have specific approvals from vehicle manufacturers, can be used in manual transmissions. Additionally, API GL-5 oils can be used in limited-slip differentials. API GL-5 gear oils are classified as suitable for use in severe conditions. They are designed for using in modern vehicles. Furthermore, these oils are also suitable for use in differentials. Manufacturers typically use various approvals for these types of gear oils and the appropriate oil can only be used if it is approved by the manufacturer.

standards.Basic Info

| spiral bevel and hypoid differentials, power dividers, Automotive Lubricant, oil-lubricated wheel bearings. | Application |

|---|---|

| Bright & Clear | Appearance |

| 95 | Viscosity Index |

| 0.909 g/cm³ | Density (29.5ºC) |

Storage

storing items in a cool place and avoiding direct sunlight when stored at room temperature.

Package

In a metal drum/ IBC

We are responsive to your needs

Contact Us Now

Marina Fajr Qeshm being as one of the largest suppliers Specialized, high-quality lubricants and bearing greases are developed to enhance the cleanliness and efficiency of food processing machinery and other applications. They are engineered to lower operating costs and extend the equipment's lifespan. These products are provided by top companies in blow:

021-77850536 021-77850569 021-77850591

98-9916593655+

info@marinafq.com