Laboratory Services

- home

- >

- Laboratory Services

Laboratory Services

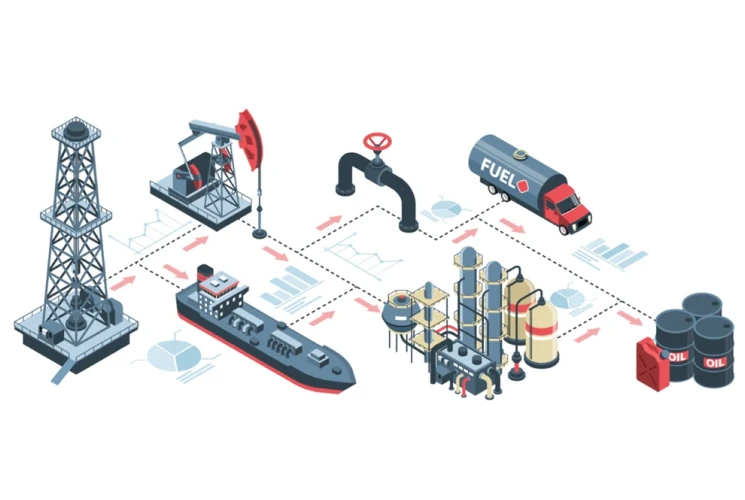

Stages of Synthetic Oil Refining

Lubricating oils are a combination of base oils and additives. The main functions of lubricating oils include:

Reducing friction

Dissipating heat

Keeping contaminants suspended

The re-refining process restores the oil to its original state as base oil. This process recovers 99% of the composition of lubricating oil from waste materials, creating an almost permanent cycle of reuse from a limited and diminishing resource.

The re-refining process removes all contaminants and returns the oil to its original state. Contaminants such as dirt, water, fuel, and used additives are eliminated through vacuum distillation. The oil is then further refined to remove any remaining chemicals, ensuring that the oil’s quality meets international standards. After re-refining, the lubricating oils are sold to third parties to be blended with additives for the production of motor oils, hydraulic oils, gear oils, refrigeration oils, vacuum pump oils, and more.

Laboratory Services

Establishment of Advanced Quality Control Systems

The establishment of advanced quality control systems in the motor oil industry aims to improve performance and extend the lifespan of engines by utilizing modern techniques for analyzing and monitoring oil quality. These systems conduct regular and precise tests, such as chemical and physical analyses, to identify contaminants, viscosity changes, and wear particles. Additionally, by monitoring the performance of additives and conducting periodic evaluations, these systems can predict and prevent potential issues in the engine. As a result, manufacturers can provide higher-quality oils that are more compatible with the needs of modern engines, thereby enhancing efficiency and reducing maintenance costs.

Laboratory Services

Modern Technologies for Testing and Quality Control

Modern technologies for testing and quality control in lubrication within the motor oil industry have significantly enhanced the accuracy and efficiency of evaluation processes. The use of big data analytics and machine learning algorithms enables manufacturers to identify patterns and trends in quality and predict potential issues. Additionally, smart sensors are capable of online and real-time monitoring of key parameters such as temperature, viscosity, and contamination, which aids in improving quality control. Nanotechnology also plays a crucial role in enhancing lubrication properties and oil stability. Furthermore, automated and robotic systems accelerate testing processes and reduce human errors. These technologies assist manufacturers in producing higher-quality oils that are more compatible with the needs of modern engines, thereby improving engine performance and longevity.