Final oils & lubricants

- Home

- >

- Final oils & lubricants

Hydrocarbon Derivatives

The industrial lubricant market

Process oils are crucial for a variety of chemical applications and are recognized as essential components in cosmetics and personal care products. Additionally, these oils are utilized in the formulation of polymers, rubber mixtures, and adhesives. It is expected that Asia will be at the forefront of lubricant consumption, as these oils enhance product quality and lower energy expenses.

Hydrocarbon Derivatives

Five essential factors in lubrication

Lubrication is a complex but vital process, and five key factors have been identified for effective lubrication:

Function

What role does lubrication oil serve? Oils perform a variety of functions, including:

Friction: Oils help minimize heat generation and energy consumption.

Wear: Oils can reduce both mechanical and abrasive wear.

Corrosion: High-quality oils protect surfaces from corrosive agents.

Contamination: Oils carry particles and other contaminants to filters and separators.

Temperature: Oils are capable of absorbing and transferring heat.

In certain hydraulic systems, oils also facilitate the transmission of power.

This highlights the importance of understanding the specific challenges associated with your application in order to select the right oil accordingly. For instance, factors such as high pressure, low temperatures, and exposure to saltwater are just a few considerations. It’s essential to choose oils that are clearly labeled to indicate their intended use and the conditions under which they perform best.

Ingredients

The components of lubrication oils are intentionally chosen based on their intended application. This principle also applies to greases. Many people may not realize that greases are essentially oils with added thickeners. The type of thickener used is crucial, as they are typically composed of fibrous particles that function like a sponge, keeping the oil in place and increasing its viscosity.

Ease of Use

Different oils require different application methods, which depend on the specific equipment involved. For example, an aerosol lubricant may suffice for easily accessible hinges, while grease can be conveniently applied by hand to a reachable gearbox.

Oil Lifespan

Oils have a defined optimal shelf life, and they must be replaced after this period. Neglecting to do so can result in metal-to-metal contact, bearing failures, and other problems that may lead to downtime and increased costs. A key way to monitor the lifespan of lubrication oil is by keeping an eye on the operating temperature of your equipment. Excessive heat can degrade lubricants, and each 10-degree Celsius (18-degree Fahrenheit) increase above 65 degrees Celsius (150 degrees Fahrenheit) can halve the lubricant’s useful life.

Calculating the True Cost

Not all lubricants are created equal. Buying a low-cost lubricant without considering the aforementioned factors can be a significant error. Equipment failures can be expensive and may trigger a chain reaction of additional issues.

Hydrocarbon Derivatives

Thermal and Physical Properties of Lubricating Oils

The thermal and physical characteristics of lubricating oils allow original equipment manufacturers (OEMs) to enhance their equipment designs. More and more, OEMs are utilizing advanced design tools to create new equipment, with lubrication oil being regarded as a vital design element in this process.

In many situations, basic information about lubricating oils is adequate, as the thermal and physical properties of a lubricant can change over time as the oil deteriorates. However, there are cases where empirical formulas and general properties are insufficient, necessitating more detailed information about the lubricating oil to optimize equipment design effectively.

Hydrocarbon Derivatives

Types of Lubricants According to Their Mechanism of Action

Boundary Lubricants

These lubricants consist of long-chain fatty acid salts, like magnesium stearate, or fatty acid esters, such as sodium stearate fumarate, which feature polar heads and fatty acid tails.

Liquid Film Lubricants

Liquid film lubricants are solid fats that liquefy under pressure, including hydrogenated vegetable oils, glycerides, or fatty acids.

Fluid Lubricants

Fluid lubricants are liquid substances that are expelled from particles when subjected to pressure.

Hydrocarbon Derivatives

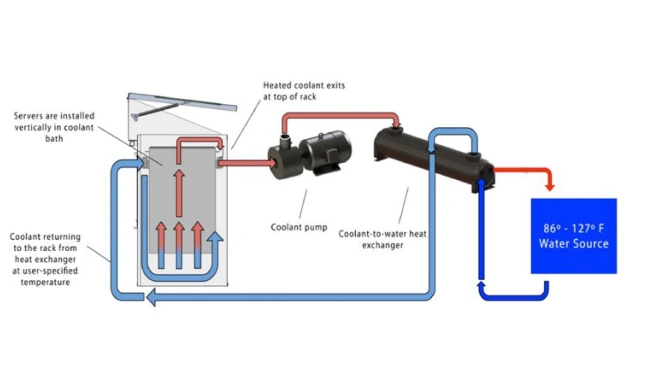

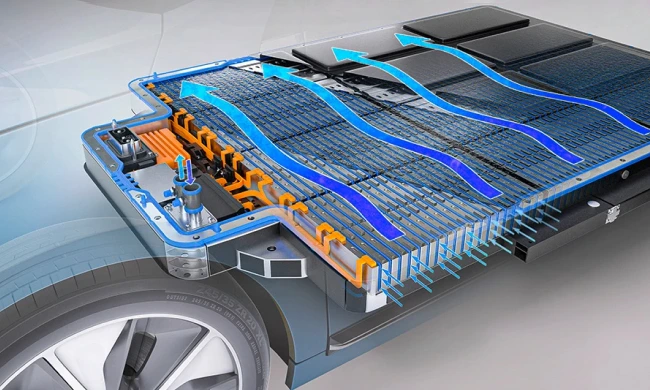

Cooling Fluids for Electric Vehicle Batteries and Data Centers

The data center industry is witnessing a significant increase in server density, creating a demand for more effective heat dissipation methods and necessitates a significant amount of energy for effective cooling to maintain optimal performance. Immersion cooling fluids are emerging as a practical solution for managing the heat generated by high-density servers. By immersing servers in a dielectric fluid, heat is absorbed more efficiently, which helps to reduce hotspot formation and maintain stable temperatures.

In response to the growing need for eco-friendly cooling solutions, a range of bio-based oils suitable for cooling electric systems has been developed. Also, efficient thermal management systems are crucial for cooling both data centers and EV batteries. Manufacturers are investing in research and development to create formulations that not only meet stringent cooling requirements but also comply with environmental regulations. As sustainable practices gain importance in the technology sector, governments and regulatory agencies are encouraging the adoption of green technologies, including immersion cooling systems that utilize bio-based oils.

Hydrocarbon Derivatives

Refrigeration Oil

Refrigeration compressor oil plays a vital role in enhancing the efficiency of refrigerant transfer while also lubricating and safeguarding machinery, particularly the compressor, in high-temperature and high-pressure conditions. The lubricant is essential for reducing friction and wear, as well as preventing oxidation; without adequate lubrication, the overall efficiency of the refrigeration system can decline due to pressure loss and increased friction from heat. Additionally, it provides a sealing effect to prevent gas or liquid leaks and helps cool the system by mitigating heat generated from excessive friction.

Refrigeration compressor oils must meet specific criteria to ensure system efficiency, with one key aspect being the miscibility of the lubricant with the refrigerant. This refers to how well the oil mixes with the refrigerant and is assessed by determining the low-temperature point at which they separate, known as the “floc point.” This must align with the relevant standards based on the type of refrigerant and the characteristics of the equipment. Ideally, the oil and refrigerant should have a balanced miscibility; if they mix too well, it can reduce viscosity, while poor mixing can hinder system efficiency.

Additional performance criteria include wear protection, thermal stability, and chemical stability, which are crucial for safeguarding machinery in environments characterized by rapid fluctuations in temperature and pressure.